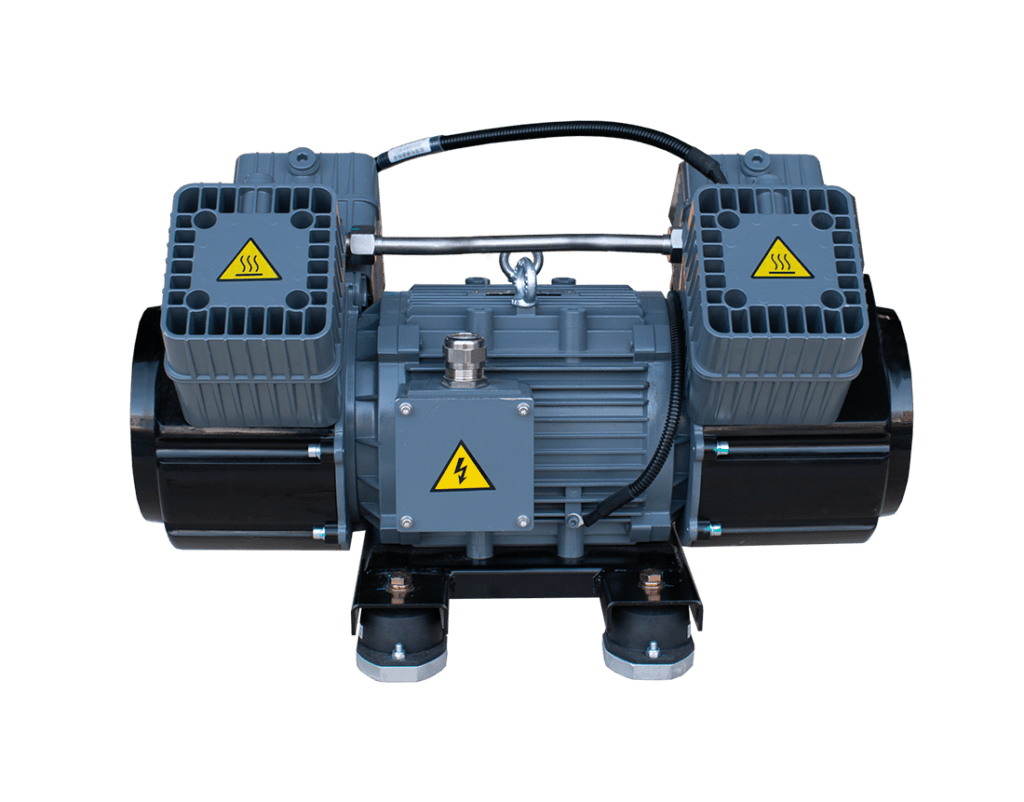

Oil-free piston compressor

Air cooled and low maintenance

Continuous operation thanks to special coating

Piston (cylinder)

A special tribological coating

on both

the piston and the cylinder wall

ensures

minimal friction,

making oil or water cooling

a thing of the past.

Motor

The engine is directly connected to the pistons

by means of a crankshaft. You benefit from this

highly efficient transmission.

Fan

The fan rotates with the pistons'

movement. This provides the necessary

air cooling, making the compressor

100% loadable.

Your benefit: Low maintenance Efficient Continuous operation No maintenance on refrigerants No maintenance on V-belts

Oil-free piston compressor

A piston compressor uses one or more pistons to compress air. The chamber in which the piston is located keeps changing its volume size. When the room gets bigger, it draws in outside air. When the room gets smaller, the air is compressed. This process releases a lot of heat. Traditional models are designed for oil or water cooling. To preserve the machine and the refrigerant, it is necessary that these refrigerants cool down, for this the machine must be stopped. Therefore, you can only use this compressor in non-continuous applications. (approx. 60% runtime/40% cooling time).

This is where Naili makes the difference for you compared to the traditional piston compressor. Due to the special coating on the piston and the inside of the cylinder, you do not need to cool with oil or water. The compressor is air cooled. Your big advantage is that you can use the compressor 24/7. In addition, you do not need to maintain refrigerants.

The traditional transmission of the energy from the electric motor to the pistons is done by means of V-belts in many piston compressors. You must maintain it properly. In addition, this form of drive results in a loss of efficiency. The oil-free piston compressors are directly connected to the electric motor via a crankshaft.

Where you normally have to perform a lot of maintenance, with this type you only need to replace the piston ring once every 8,000 hours; a few minutes' operation.

Naili saves you maintenance!

Traditional

Oil and water cooling

These refrigerants must cool down, forcing you to interrupt operation.

Intermittent operation

Due to cooling time, you can only use the traditional compressor for non-continuous operation.

Energy transmission through V-belts

The downside is that you have to maintain the V-belts and it reduces your efficiency.

Naili

Air cooled compressor

A low friction coating on the pistons and cylinders allow air-cooling.

Continuous operation

There is no cooling time for refrigerants and no time spent maintaining them.

Energy transmission through a crankshaft

These compressors are directly connected to the electric motor via a crankshaft.

Find the most optimal use

Energy consumption and control

Compressed air consumes a lot of energy. We therefore advise you to look for the correct and most optimal use of the absorbed energy. From an energetic point of view, the most efficient situation is if your compressor is off when the operating pressure is reached. However, in practice an on/off control is often not possible. Due to the narrow set pressure range, the compressor switches too often, causing the motor to wear too hard.

For that reason it is desirable that the motor adjusts its speed to the demand, so that it does not have to switch on/off every time the compressed air consumption does not require 100% power. As a result, the need to set overpressure in the system to accommodate fluctuating demand is no longer relevant. The speed will be increased when the pressure in the system decreases. The control of a frequency-controlled compressor keeps the pressure at the set desired pressure through PID calculations, making increased energy consumption due to overpressure a thing of the past.

EVERY BAR PRESSURE IS 7% MORE ENERGY

Tailor your setup

Compressed air is expensive because over 85% of the used electrical energy is converted into heat and only 15% into compressed air energy. In addition, the higher the pressure, the more energy is required. Each additional bar of pressure that your compressor has to generate will cost you 7% more energy.