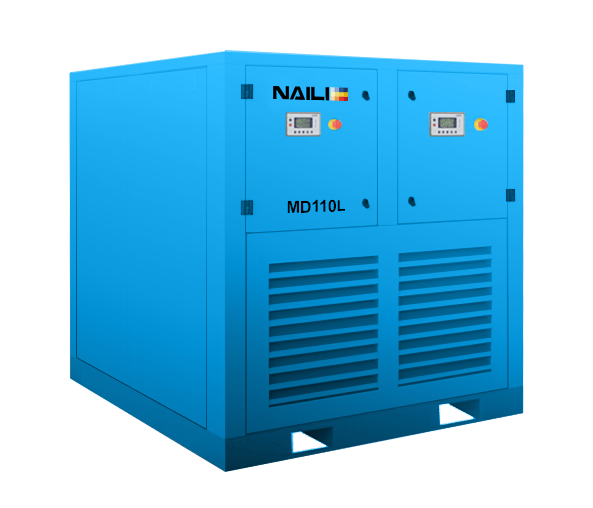

MD-series

powerful and reliable

MD-series rotary vane compressor

Pressure gauge

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor.

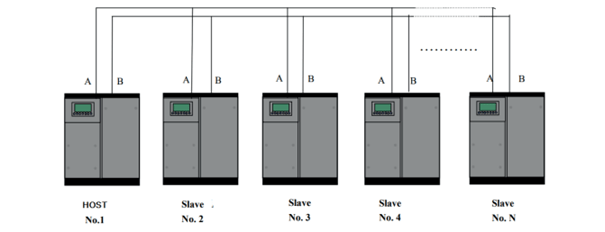

The MD series contains the machines with the largest air output of the Naili product range. The compressors are made up of several air-ends, which are placed together in one sound-insulating cabinet. This makes these compressors very quiet to use. You can therefore position these compressors close to a workplace, in accordance with occupational health and safety regulations. The housing can be dismantled very easily, making it easy to maintain the compressor.

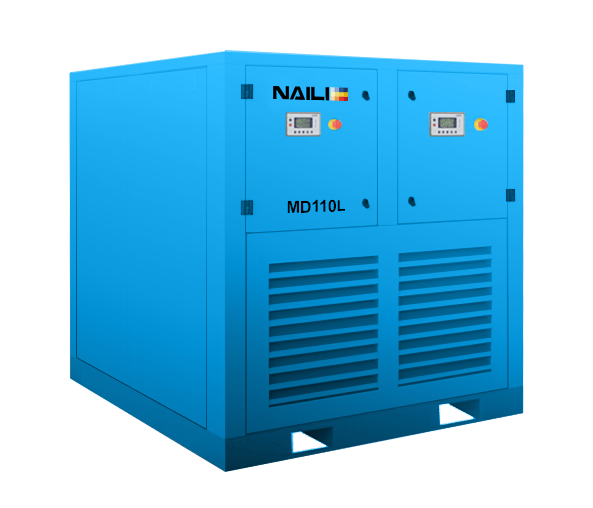

These compressors have a simple control that supports the user during use. You have the option to set up each compressor in cascade (max. 16) with this control. In this way you achieve the desired air output and you observe the correct load per machine.

The temperature of the outgoing compressed air is approx. 10 °C above ambient temperature thanks to the large radiator. This makes it possible to connect the compressor directly with a compressed air dryer, before storing the compressed air in a tank.

The MD-series has few parts subject to wear, which saves you on maintenance.

With a Naili rotary vane compressor from the MD-series you have a very reliable, powerfull, maintenance-friendly and low noise compressor, suitable for a long service life.

Additional energy saving and backup

Cascade setup

It is cost-effective to connect several compressors in a communicating setup. Therefore it is important to understand what volume and pressure of compressed air is required in a certain period of time. Always have your dealer or installation partner perform a compressed air measurement. These insights will help you to a setup that optimally follows the daily use. In a cascade setup you save considerably on energy consumption by switching multiple compressors with a lower capacity. The supporting compressors are only switched on when a peak demand occurs. They are off for the rest of the day, so they don't require any energy. A huge energy saving that will benefit your energy bill.

The cascade control divides the necessary running hours evenly over the various machines. This means you spread the load on your compressors.

An additional advantage is that you always have a backup compressor in case of maintenance, so that your production process continues without any problems.

Your benefit: Reliable No damage to the rotating parts Extremely quiet

Rotary vane compressors

An extremely simple and reliable technique is used in a rotary vane compressor. You may know it from a vacuum pump. An electric motor is connected in-line to a rotor in which (steel) vanes are placed. The rotating movement of the rotor pushes the vanes outwards.

The rotor is eccentrically placed in the housing and ensures that the vanes form chambers around the rotor. As the chambers are reduced, pressure builds up.

Oil provides lubrication, cooling and sealing. It is therefore very important that you keep the oil in the right condition, as with any oil-containing machine.

The linear connection between motor and rotor ensures that there is no lateral load on the bearing. As a result, there will be no damage to the rotating parts. Naili limits your maintenance to the replacement of filters and oil. This makes this type of compressor very attractive to the user.

Moreover, this technique ensures that these compressors are very quiet in use. This allows you to place these compressors close to a workplace.

Performance

A rotary vane compressor has a very efficient energy transfer with low resistance because no energy is lost in V-belt or gearbox transmissions.

This provides energy savings of up to 20% compared to other common technology on the market. A lifetime of 70,000 operating hours is no exception for a vane compressor.