Agriculture

Very quiet in operation and easy to maintain

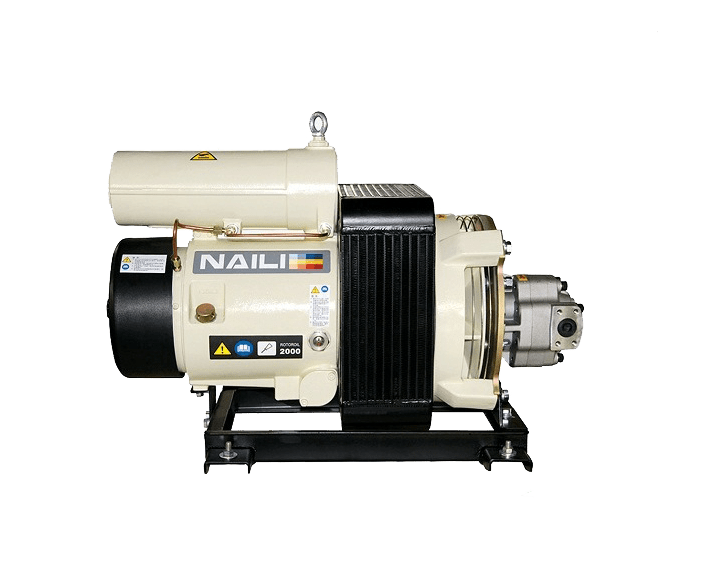

Rotary vane compressors for the agricultural sector

The agricultural industry continues to develop in terms of automation and efficiency. This includes the robotisation of the milking process, but also the need to keep tires at the right pressure to prevent increased fuel consumption due to driving with tires that are too soft or the agricultural land being compacted by tires that are too hard.

Especially for this sector, Naili has developed a compressor that fits in with the challenging environment in which work is done. Materials have been selected to guarantee a long lifetime.

Naili has developed the AH series especially for mobile applications where electricity is not available, but where hydraulics are.

By replacing the electric motor for an hydraulically driven motor, it is possible to have the compressor run along with the hydraulic circuit of your vehicle.

The compressors in the AH series are standard built on a frame. Therefore, you can easily install them.

Optionally, you can integrate an aftercooler for the compressed air in addition to the oil cooling. By post-cooling the compressed air, a large part of the moisture present condenses.

An extremely simple and reliable technique is used in a rotary vane compressor. You may know that of a vacuum pump. An electric motor is connected in line to a rotor in which (steel) vanes are placed. The rotating movement of the rotor pushes the vanes outwards.

The rotor is placed eccentrically in the housing and allows the vanes to form chambers around the rotor. Because these are reduced, pressure can be built up. Oil provides lubrication, cooling and sealing. It is therefore very important, as with any oil-containing machine, that you keep the oil in the right condition. Due to the linear connection there is no lateral load on the bearing. This contributes to the fact that there is no damage to the rotating parts to be expected; which is a major cause of malfunctions with other types of compressors. As a result, the maintenance of a rotary vane compressor is limited to replacing filters and oil, which makes it very attractive for the user.

Hydraulic drive

Especially for mobile applications, Naili has developed a series that is hydraulically driven. This allows you to use the PTO on the towing vehicle or integrate the compressor into your hydraulic circuit without the need for electricity.

Integrated air cooling and conditioning

Because compressed air normally leaves the compressor warm and contains a lot of moisture, this will cause many problems in your system without proper conditioning. That is why Naili, together with leading partners, has developed a compressor that supplies conditioned and therefore usable compressed air. Our development, your advantage!